About Company

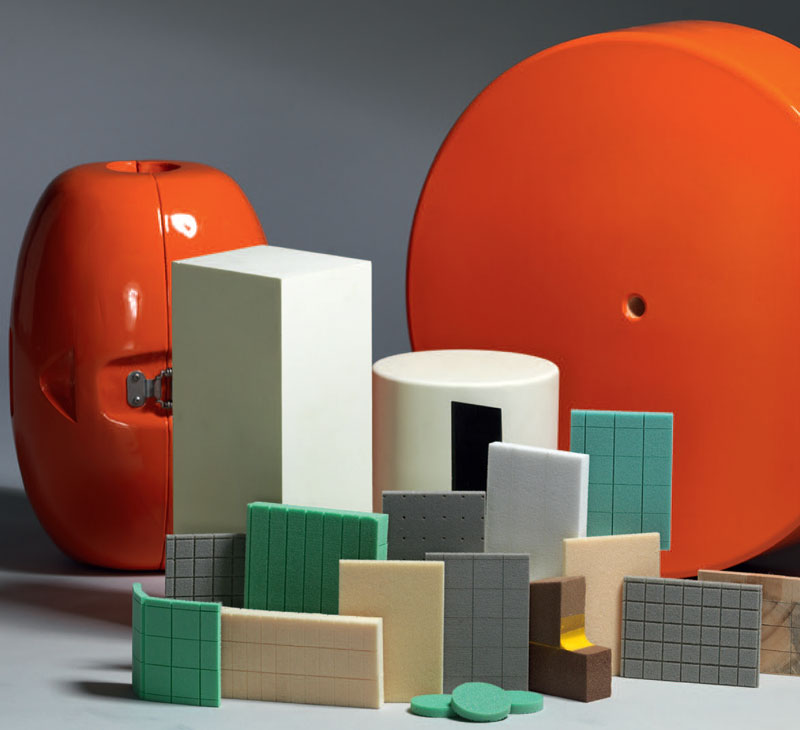

DIAB has been at the leading edge of composite core material development for over fifty years, supplying a wide range of markets including marine, wind energy, transportation, aerospace and industry.

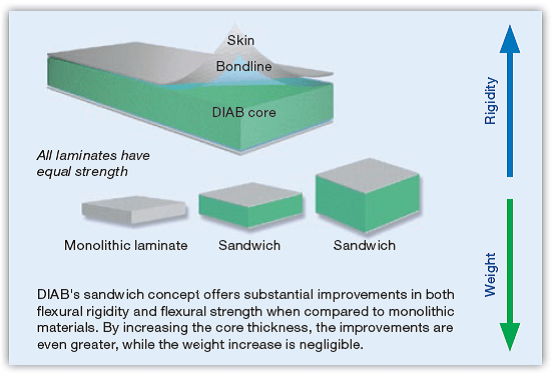

At DIAB, our customers’ needs are at the center of all we do. We like to think our deep understanding of your needs has given DIAB a unique position in the industry. We know that designing high-performing applications using sandwich composites — whether you define high performance as low weight, high durability or low cost — involves several key factors, which all interlink. We take a holistic approach in close cooperation with our customers, ensuring your products become stronger lighter and more competitive.

Core: Selecting the right core material is crucial as it defines the mechanical properties, weight and characteristics, such as FST of the structural part of an application.

Finishing: Selecting the right finishing enables a fast, high-quality manufacturing process, as well as allows for creating curvatures and geometries.

Kits: Pre-cutting the core (kits) increases quality and efficiency and can significantly reduce cost.

Manufacturing: Choosing the right manufacturing process is essential for optimization. DIAB core infusion is a continuously refined manufacturing process for sandwich composite parts.

Competence: All of the factors above interlink and cannot be viewed in isolation. To reach your targets, seek out a holistic perspective for a complete solution taking all the above into account.

This is what DIAB does. High-performance core materials and sandwich composite solutions that make your products stronger, lighter and more competitive.